What Is the Main Concern When Stripping Wire?

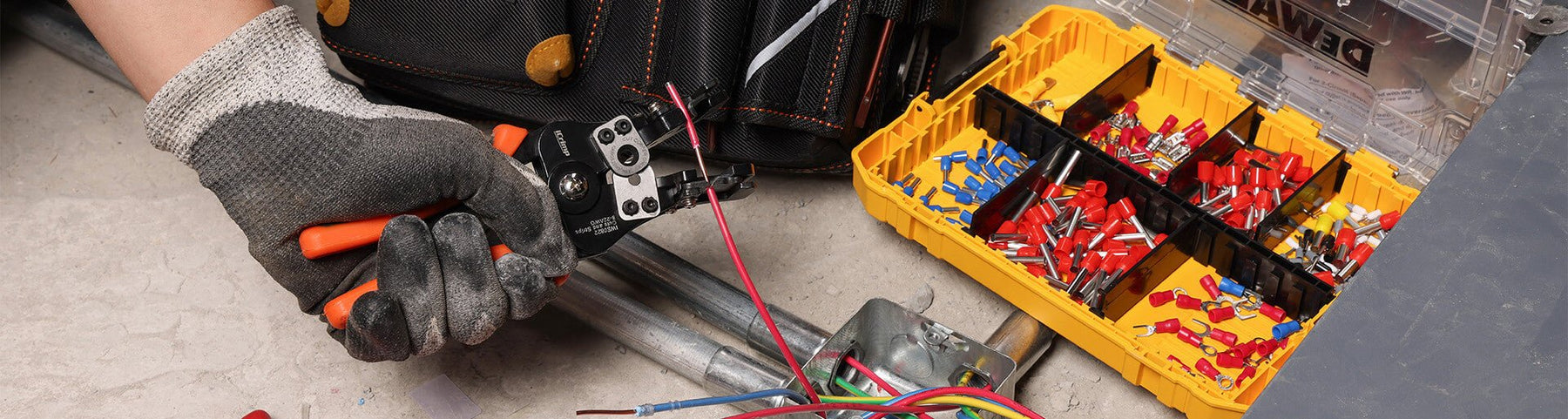

Stripping wire remains one of the preliminary activities carried out in practically all electrical projects. However, improperly stripping may pose significant challenges ranging from poor connection to worst electrical risks. Your electrical work will be safe and intact if you know the major issues and how to resolve them. In this post, we will go over the concerns when wire stripping and how selecting the appropriate wire stripper tool can significantly impact the process.

The Importance of Proper Wire Stripping

Wire stripping, for instance, using the IWS-D10 Wire Stripper, removes a wire's outer layer to expose the inner layer, which is the conductor. It is also crucial to establish safe electrical connections to conduct electricity. However, one has to note that force on the wire needs to be applied carefully as too much or minimal force may comprise the wire functionality. When the process of wire stripping is concerned, the primary danger is to damage the conductor or strip too little insulation for it to perform effectively or safely.

Potential Issues as a Result of Inappropriate Wire Stripping

1- Damaged Conductors

The primary concern is often not to make severe cuts on the conductor when stripping the wire. It can happen when the force exerted is too much, or the tool is poorly maintained. Using a high-quality tool such as the HS-D2 Automatic Electric Wire Cable Stripper increases the accuracy of the cutting edges of a wire stripper, reducing damage to the conductor. Damaged conductors weaken the wire's structural integrity, leading to:

- Reduced conductivity

- Increased resistance leads to overheating

- Intermittent Connections

2- Insufficient removal of Insulation

Leaving a conductor partially bare means weak or partial contact from inadequate insulation stripping. It is also essential to strip it effectively to uncover the preferable wire insulation for a particular use. This issue causes:

- It malfunctions in forging or welding processes and other applications, allowing direct contact with a conductor.

- It causes short circuits.

- It causes electric shock and fire danger.

3- Over-Stripping

The essence of stripping is to peel only the amount needed to give the connection, while the other part of the wire has to remain shielded. Removing too much insulation can expose more of the conductor than necessary, leaving it vulnerable to:

- It can cause accidental contact with other wires or any conveyance area, such as the floor, ceiling, etc.

- Short circuits.

- Eroded through time because of the surrounding environment.

4- Inconsistent stripping

Some of the most common improper tools are utility knives and pliers, and their use leads to irregular stripping and poor conductor action. These tools lack the precision of dedicated wire strippers and may lead to:

- Jagged insulation cuts

- Reduced wire strength

Significance of Wire Stripping

A wire stripper is a well-designed wire stripping tool precisely made for the swift wire stripping process. The wire stripper is engineered to:

1- Consistent Electrical Contacts

It removes the coat, unearthing the naked copper conductor best suited to make a firm connection with terminals, connectors, or other wires.

2- Preventing Short Circuits

Inadequate insulation removal means that some cables touch or come into contact with the ground and create a short circuit, which may destroy equipment, trip circuit breakers, or cause fire.

3- Trimming a wide range of wire thicknesses accurately

Avoid exposure of wire conductors in any attempt to touch the conductor or drag it through any surface, as this may be damaging.

4- Ergonomic performance

Provide comfortable handles to help with clamping and less chance of fatigue from your hand muscles.

5- Ensuring Safety

An inadequate striping of the cables brings about a considerable danger of electrical shock, mainly when operating in a high-voltage circuit.

6- Achieving consistency and aesthetic

Strip with equal thickness for the desired professional finish.

7- Consistent Current Flow

Correctly stripping the wires helps to convey current without much resistance to heat, which is dangerous.

Read more: What are the Steps in Cable Crimping?

Ways on How to Achieve Proper Wire Stripping

1- Choose the Right Tool

Ensure your wire stripper is appropriate for the wire type and gauge you work with. A good example is the IWS-085 One-handed Multi-Tool, AWG18-3 Wire Stripper.

2- Inspect Your Tool Regularly

A sharp cutting edge and a well-maintained tool are essential.

3- Practice Precision

Aligning the wires is always essential to avoid mistakes. It is recommended that the wire be appropriately placed in the stripper's slot.

4- Avoid Nicking the Conductor

While stripping, be extra cautious and ensure that none of the wires is cut during the process.

5- Inspect the Wire After Stripping

Always check that the insulation has been stripped off well and that the conductor is also intact, which is paramount.

6- Practice Safe Work Habits

Work under certain precautions for electrical installations, such as turning off circuits before wiring.

Bottom line

The main factor that must be considered while stripping wire is ensuring that the conductor remains undamaged and is exposed to the extent adequate to provide good connections. Faulty conduits, improper stripping of the insulations, and use of substandard tools may jeopardize the safety or even the efficiency of electrical work. When you use a tool such as the iCrimp wire stripper, it becomes very easy to strip wires, as you will be confident and precise.

References