Is Propress Better Than Solder?

Soldering is one of the traditional methods of creating copper pipe connections in the plumbing industry. However, other methods, such as pressing, have emerged and dominated the industry in recent years. Propress tools and fittings have increasingly become popular in residential and commercial plumbing projects. What makes pressing is that you don't need heat to create connections: fittings have a built-in O-ring that creates an air and water-tight seal when pressed to a pipe.

What has contributed to this significant shift? Is Propress a better option compared to solder? Let's find out more down here.

Read more: Can I Use PEX Crimp on Copper Pipe?

Why Propress is Better than Soldering?

Here are five reasons why pressing copper pipes is better than soldering:

1. Efficiency

Efficiency is the main reason pressing methods outdo conventional soldering. First, pressing doesn't require extensive training and experience; therefore, a beginner can easily make reliable pipe connections. Another aspect is that making a press connection takes incredibly less time (a few seconds to minutes) than soldering: soldering is time-consuming. Also, Propress allows one to make reliable and tight pipe joints even when working with wet pipes, while soldering requires you to drain and dry pipes completely before making any joints.

2. Safety

One of the disadvantages of soldering is that it is a fire hazard due to the open flame; for that reason, some projects will require you to acquire a hot work permit. Additionally, fumes from blazing can be harmful when inhaled by plumbers and other occupants. On the other hand, pressing only requires a Propress tool and fittings, and no fire hazard is involved. As a result, it saves time and allows you to work on a wide range of projects, including buildings such as chemical plants, hospitals, etc.

3. Accuracy and reliability

With a well-calibrated Propress tool, you can easily make accurate and reliable pipe connections. A Propress tool produces enough pressure to create a strong, tight, long-lasting pipe connection resistant to leaks and corrosion for a wide range of plumbing and HVAC applications. It is also relatively easier to achieve uniformity with Propress joints than soldered ones.

4. Cost-effective

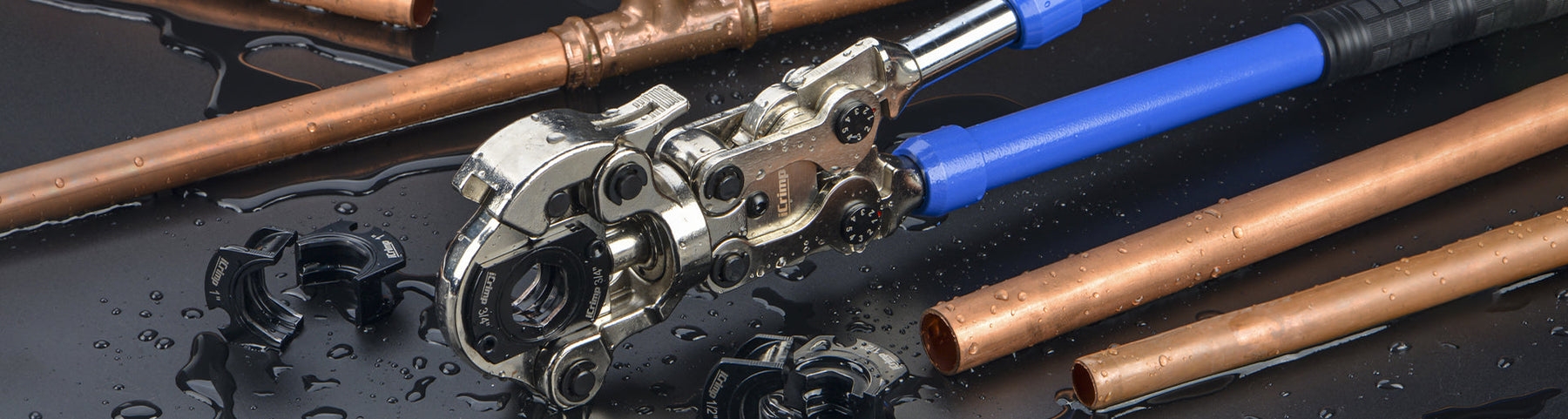

Pressing is not time-consuming and requires less labor, making it a cost-effective method, especially for large projects. Also, a single Propress tool like the iCrimp IWS-1632AF Press Tool is enough to create hundreds of thousands of connections. On the other hand, creating a single solder joint requires a lot of things, such as a soldering torch, solder wire, sandpaper/cloth and flux, which ultimately increases the overall cost.

5. Versatility

Soldering is only applicable when dealing with copper pipes. On the other hand, pressing is a versatile connection method that can be used to create connections between different types of pipes used in the plumbing industry, such as PAP, PEX and copper.

Read more: Can I Fix a Leaky Pipe Myself?

Bottom line

Propress is one of the great innovations in the plumbing industry: it's cost-effective, safe, efficient, versatile and reliable compared to typical pipe connection methods such as soldering. As a result, it keeps gaining popularity among tradespeople and DIY enthusiasts.

Are you looking for a quality Propress tool for your upcoming projects? iCrimp is the best platform for buying affordable, ergonomic, and quality Propress tools for pipes of all sizes. Our expansive stock of tools includes pressing tools for common types of tubing materials used in the plumbing industry.

References